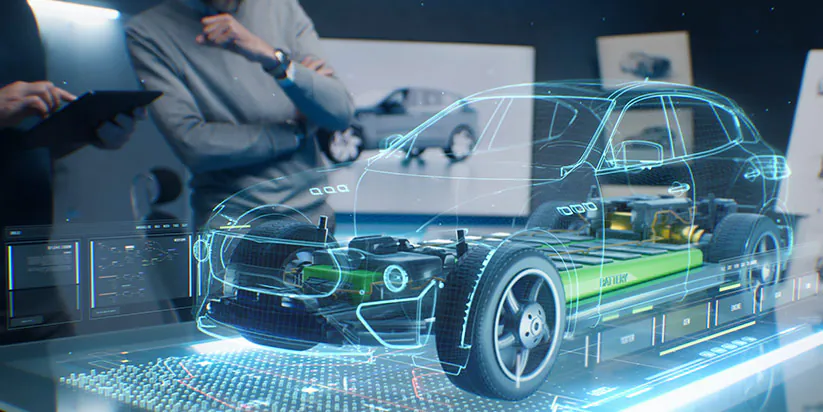

©Framestock – stock.adobe.com ©Framestock – stock.adobe.com

©Framestock – stock.adobe.com

©Framestock – stock.adobe.com

©Framestock – stock.adobe.com

Case Study

Production Ramp-Up at Supplier Battery Systems

Battery Assembly in the Automotive Supplier Industry

These articles might also interest you:

©Framestock – stock.adobe.com

©Framestock – stock.adobe.com

Case Study

These articles might also interest you: