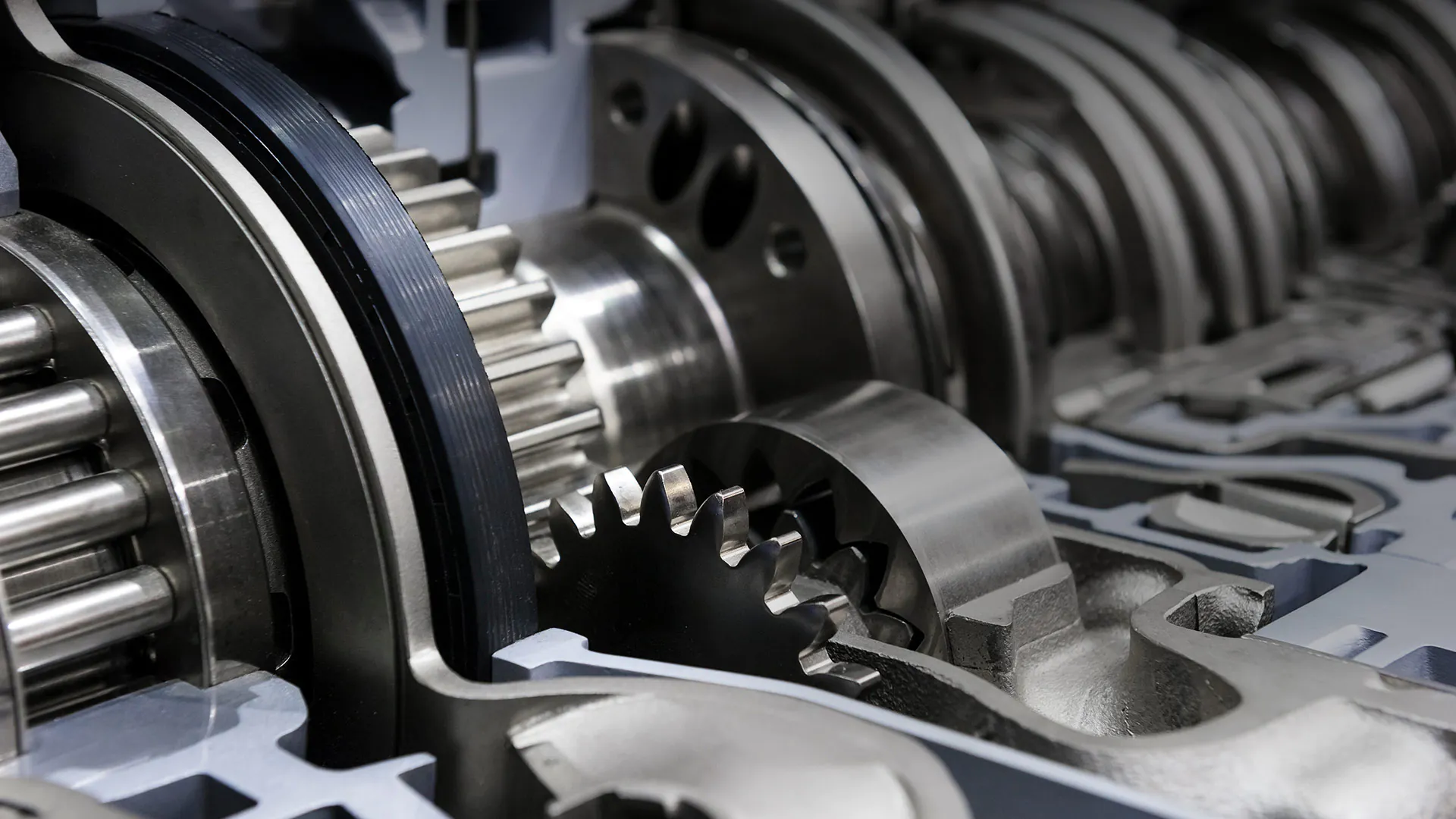

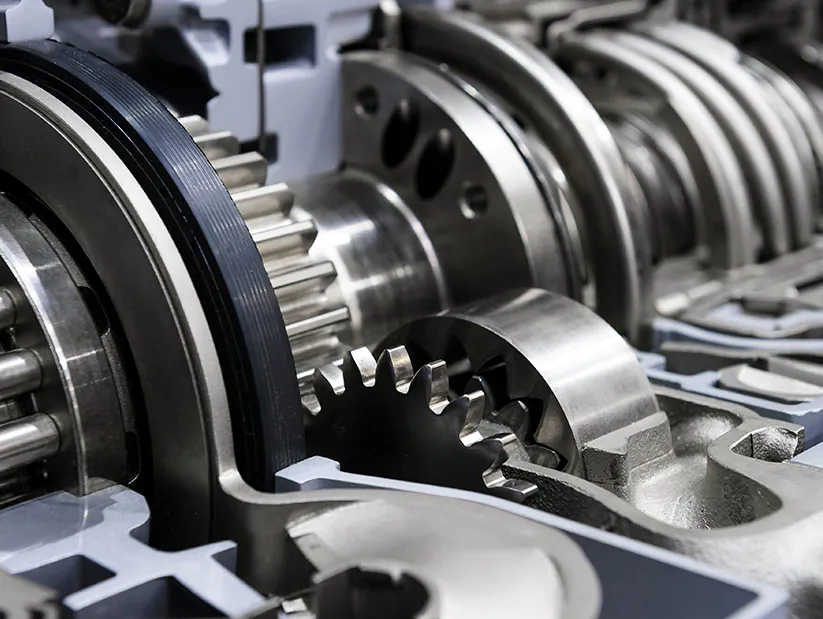

©antonmatveev – stock.adobe.com ©antonmatveev – stock.adobe.com

©antonmatveev – stock.adobe.com

©antonmatveev – stock.adobe.com

©antonmatveev – stock.adobe.com

Case Study

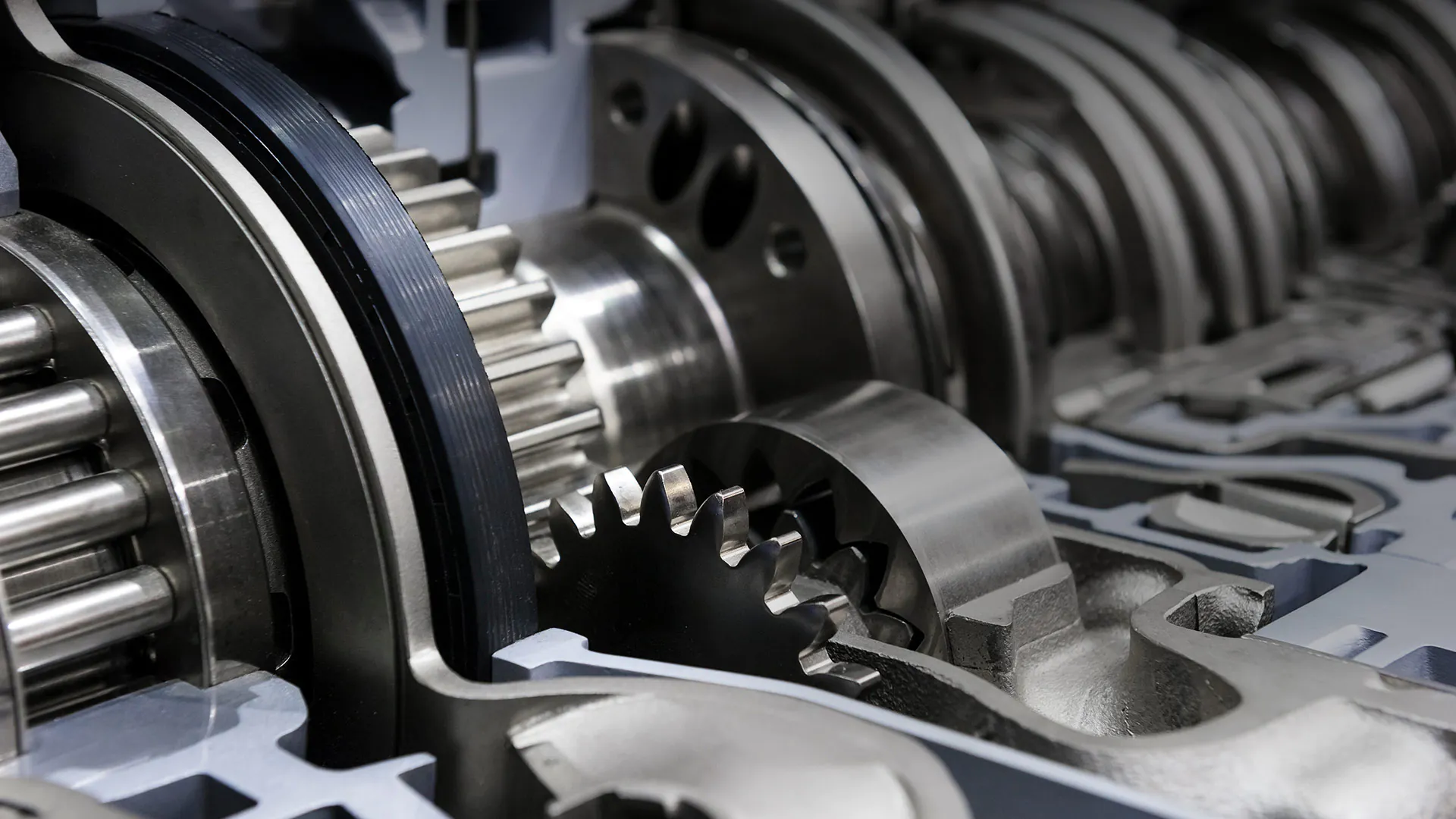

Production ramp-up at an international industrial company for vacuum solutions

Production Ramp Up

These articles might also interest you:

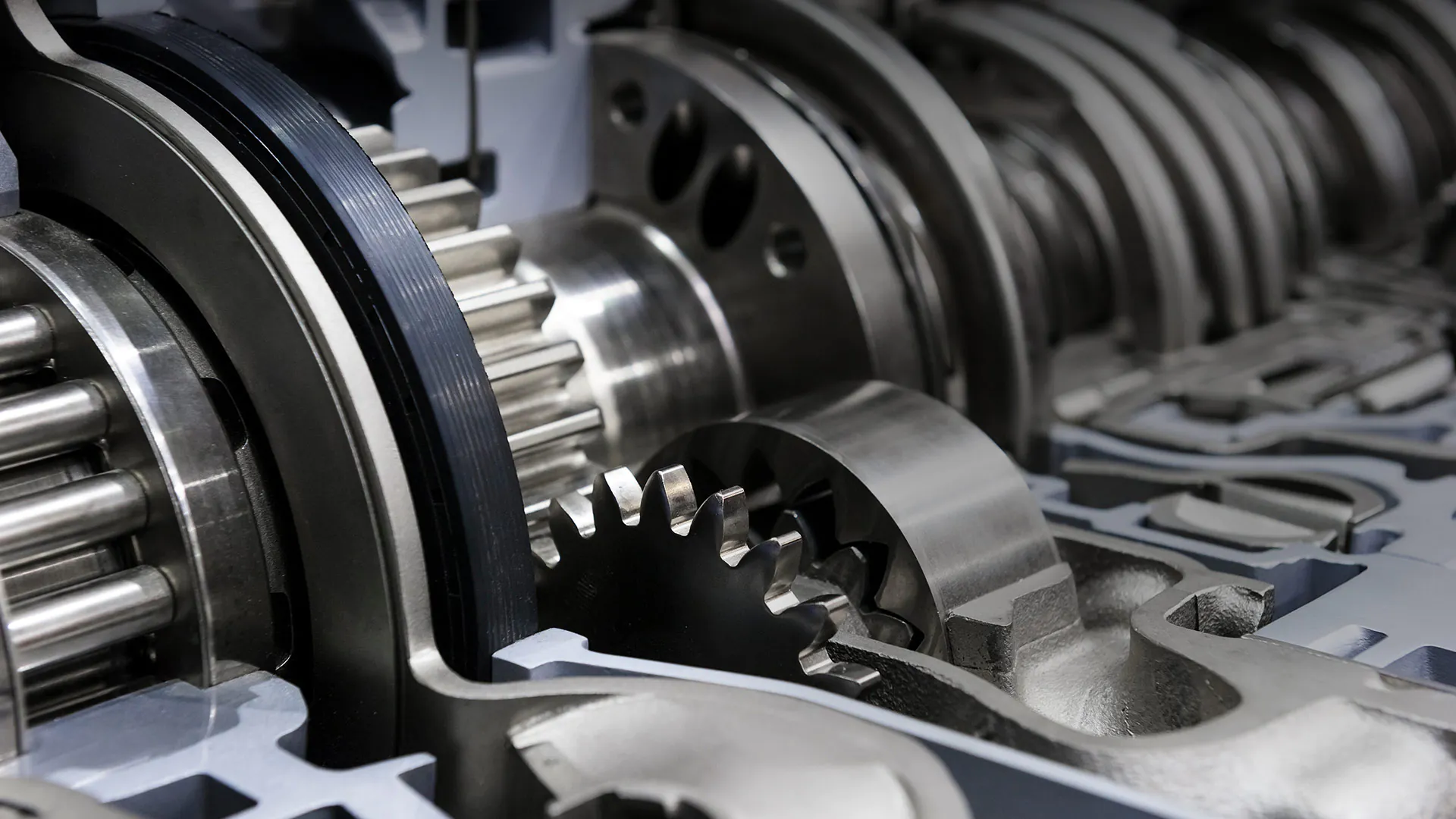

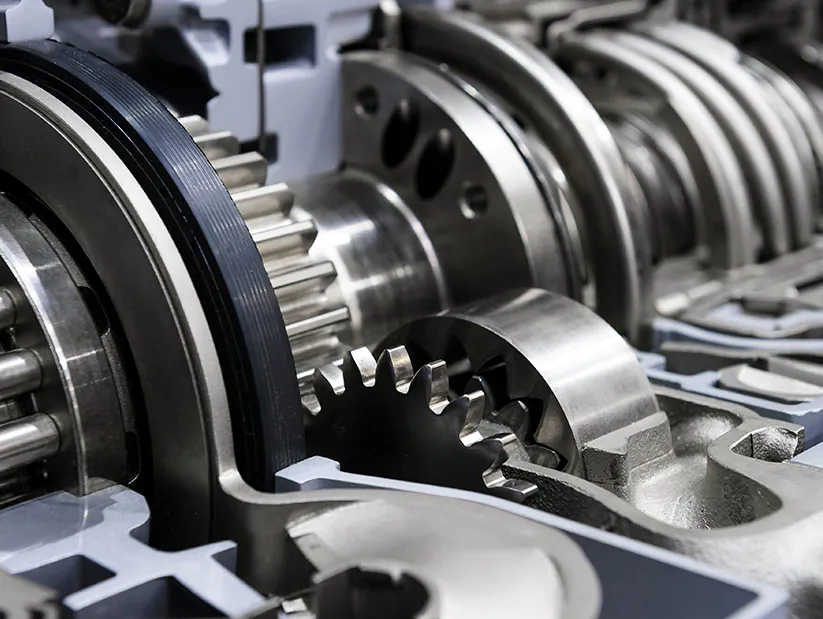

©antonmatveev – stock.adobe.com

©antonmatveev – stock.adobe.com

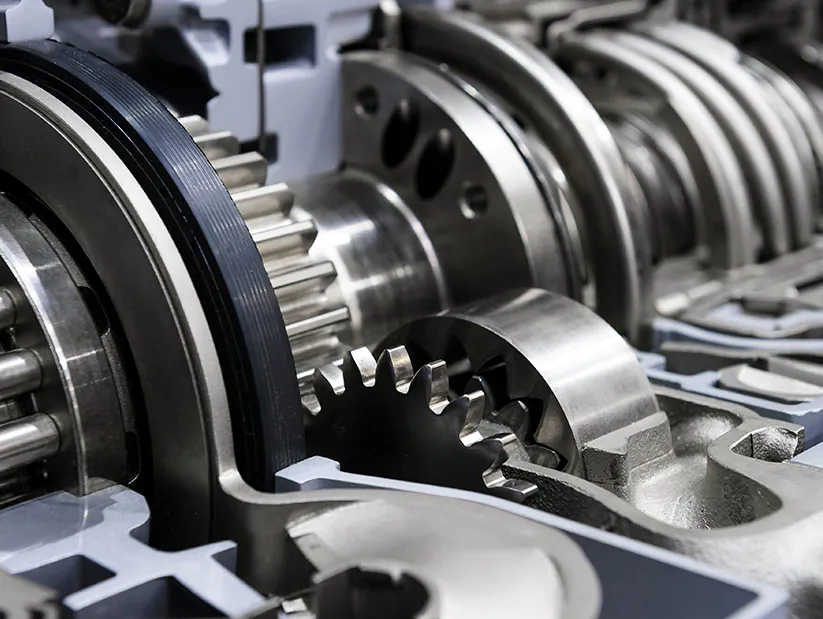

Case Study

Production Ramp Up

These articles might also interest you: